ProBot™

ProBot™

ProBot™ is a Microsoft® Excel®-based application designed to automatically monitor and provide expert advice on the performance of a process, a sequence of unit operations, or a specific equipment item. As the most experienced engineers retire they take their years of hard-won knowledge with them so their accumulated expertise is forever lost. ProBot is one way to retain it.

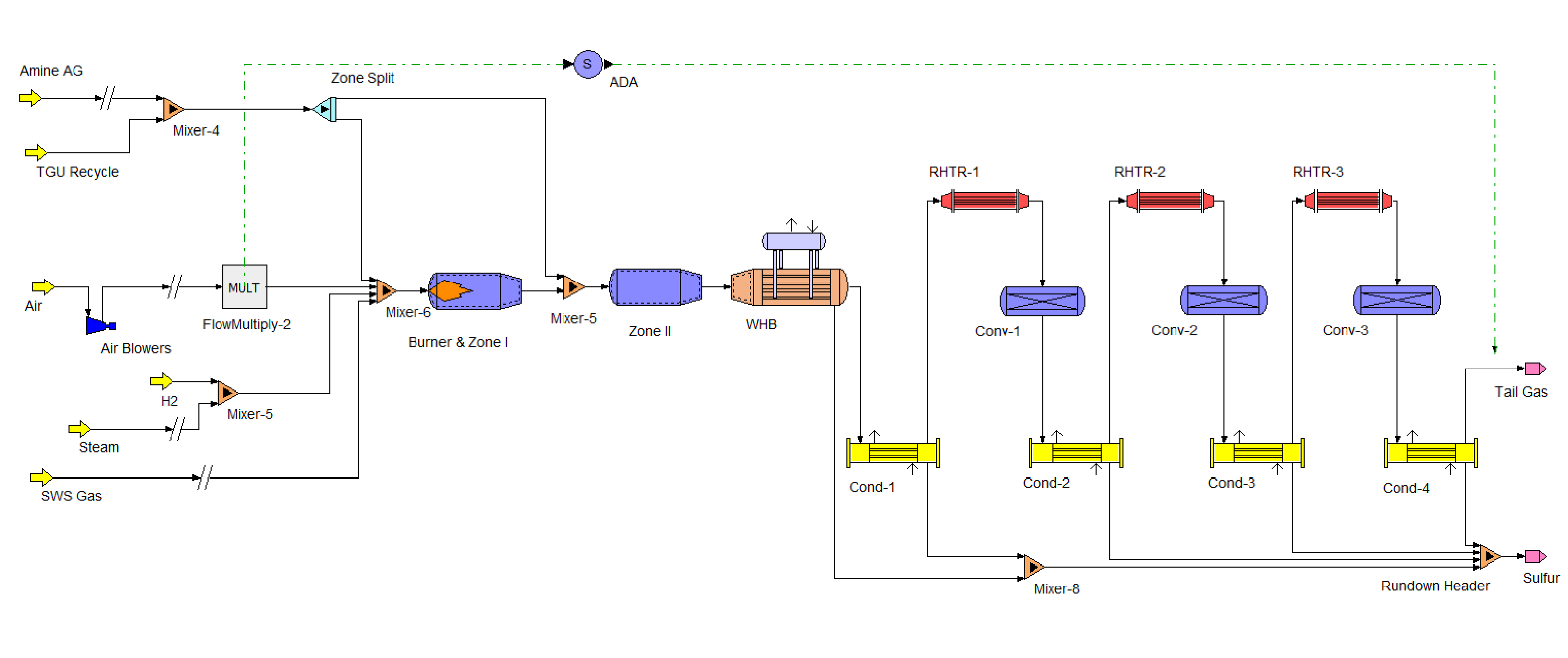

ProBot is a repository of experience used to suggest remedial steps when the monitored item's performance deviates significantly from expectations. ProBot is connected to a data historian, for example, or a DCS which provides the information needed to run a simulation, and which also contains the performance metrics needed to compare with the simulated or expected performance. To assess the expected performance, ProBot™ uses the ProTreat® and SulphurPro® simulators whose solid engineering-science basis makes them fully predictive with a track record of high accuracy and reliability. For a more in-depth exposition, see the rationale behind ProBot's development. For a quick summary, look here.

OGT's consulting team is ready to help you connect ProBot into your system and start reaping the benefits of on-line monitoring, and the early detection of faults and conditions that, undetected, may lead to potentially catastrophic equipment failure, outages, and huge lost revenue and unrealized profits. A ProBot license includes a fixed number of consulting hours to help you connect ProBot into your system.

ProBot is currently being used at a group of refineries in the USA and it is undergoing field trial at several other plants in Canada and the USA. Application to an operating SRU is detailed here.

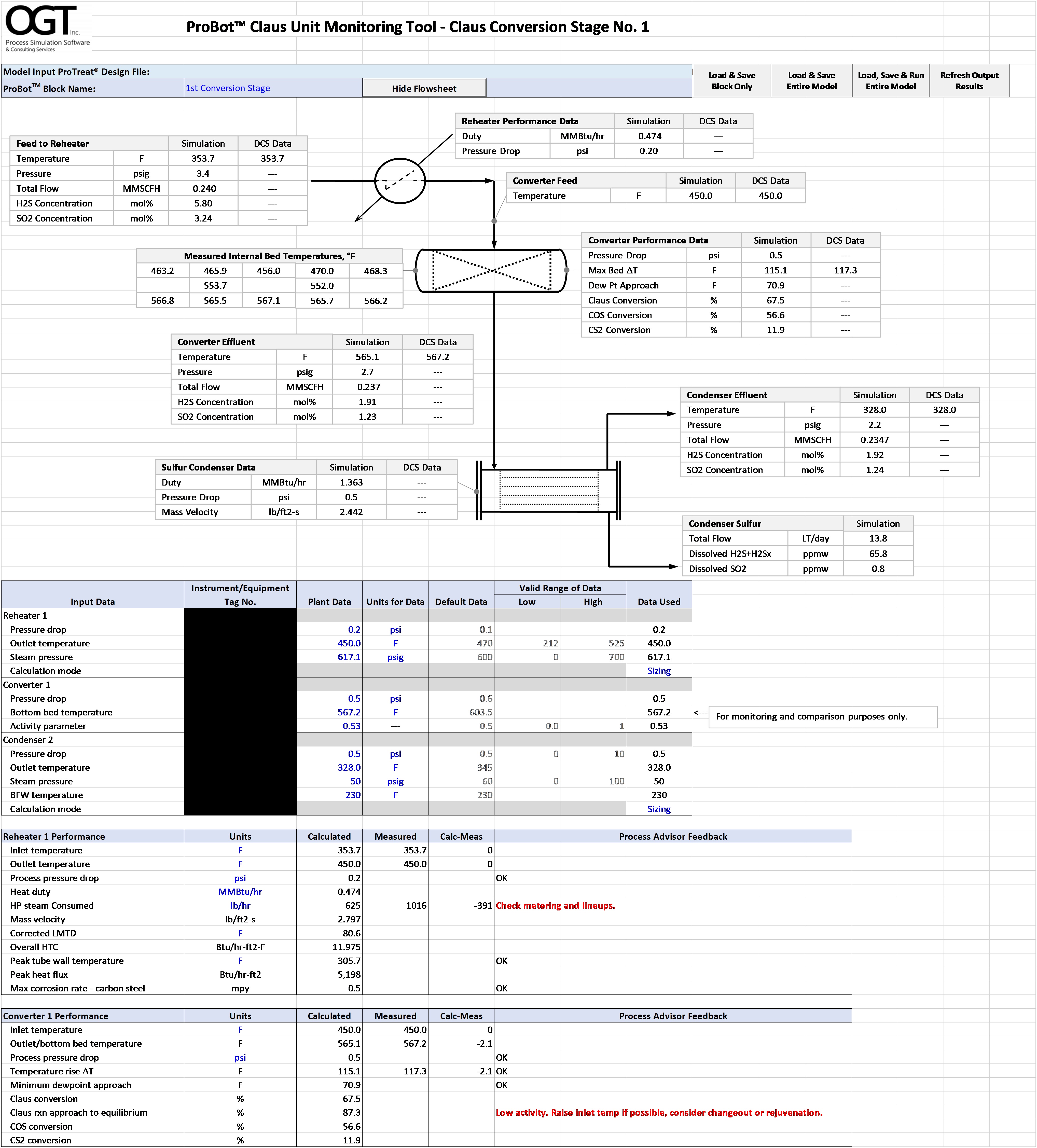

For the sulphur plant shown here, the spreadsheet below shows sample ProBot output for the first catalytic converter stage: