Waste Heat Boilers

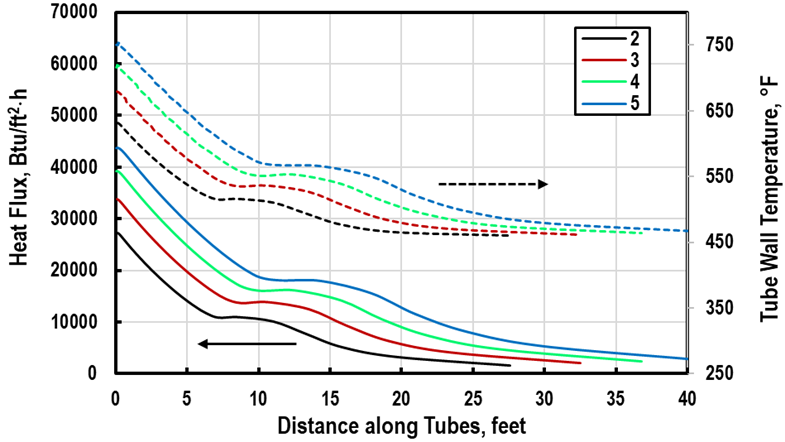

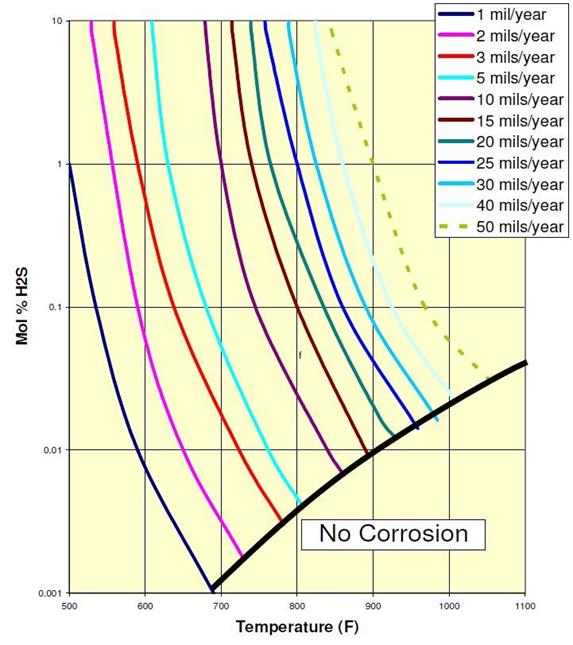

A tremendous amount of energy in the form of high pressure steam can be recovered from an SRU. For that reason alone, the WHB is an item of great importance in an SRU. The SRU operates at high pressure on the utility side but low pressure on the process side so there is a high pressure difference across the tubes. The process side contains very hot combustion gas with significant H2S content which subjects the tubes and the tube-to-tubesheet joint to sulphidic corrosion. A WHB is a very expensive equipment item often with a very long lead time for replacement and subject to catastrophic failure. When the WHB fails the refinery cannot meet sulphur emissions regulations and must be shut down. Not only is the WHB itself expensive but the consequential lost profit that accrues from an extended refinery shutdown greatly exceeds WHB replacement cost. Tube wall heat flux and temperature are critical parameters. A good model can simulate this equipment quite accurately and forewarn of impending disaster.

By directly calculating heat flux and tube wall temperature through the entire length of the waste heat boiler (WHB) tubes, SulphurPro® can help determine if past or present operating conditions are likely to cause overheating of the tubes. SulphurPro can also assess the possibility of tubesheet failures by determining sulfidic corrosion rates as a guide to understanding operating limits and implementing guidelines for future operations. You can also determine the level of deactivation in the converter catalyst beds caused by upset conditions as well as sulphur condenser performance issues, e.g., plugged tubes or sulphur carryover, to determine if the current operating conditions will be adequate to meet specifications and regulations until the next planned turnaround. Accurately assessing the effects of SO2 breakthroughs into the amine-based tail gas treating unit (TGTU) is also crucial in understanding the level of damage caused and helping to assess whether to bring the unit down for maintenance or continue running until the next planned shutdown.

Time-on-stream & Unplanned Outages

By directly calculating heat flux and tube wall temperature through the entire length of the waste heat boiler (WHB) tubes, SulphurPro® can help determine if past or present operating conditions are likely to cause overheating of the tubes. SulphurPro can also assess the possibility of tubesheet failures by automatically determining sulfidic corrosion rates as a guide to understanding operating limits and implementing guidelines for future operations. You can also determine the level of deactivation in the converter catalyst beds caused by upset conditions as well as sulphur condenser performance issues, e.g., plugged tubes or sulphur carryover, to determine if the current operating conditions will be adequate to meet specifications and regulations until the next planned turnaround. Accurately assessing the effects of SO2 breakthroughs into the amine-based tail gas treating unit (TGTU) is also crucial to understanding the level of damage caused and helping to assess whether to bring the unit down for maintenance or continue running until the next planned shutdown.